DECACOTE

INTRODUCTION:

Mould & Core Coatings are used in foundry to provide smooth surface on steel and iron casting body. It is available with various bases like as follows:

- Zircon (Water, Spirit/Alcohol base)

- Graphite (Water, Spirit/Alcohol base)

- Magnesite (Spirit/Alcohol base)

APPLICATION:

When coating is applied on mould and core surface either by brushing, spraying, flooding, swabbing or dipping, it fills the gap or pores between the sand particles and provides an impermeable refractory surface as well as an inert layer between metal and sand. To avoid sand fusion and metal penetration a proper coating thickness should be applied on mould and core surface, for this a number of thin coats may be required and it should be properly dried before pouring of metal to avoid the pin/blow holes in the castings.

DECAFLUX G W P 1020 (Graphite Water Base):

DECAFLUX G W P 1020 is in Dark Grey/ Black coloured water base coating containing High Quality Refractory Material & Graphite. It imparts low reactivity to the metal oxides & delivers excellent casting surface finish especially at High Pouring Temperatures.

It is suitable for dipping applications of Resin Bonded Complex core in the production of the castings like Cylinder Blocks, Cylinder Heads & the hydraulic components. It is recommended for Grey Cast Iron, S. G. Iron & Non Ferrous Alloys.

PHYSICAL PROPERTIES:

- Colour – Dark Grey/ Black coloured (Water Soluable)

- Specific Gravity – 1.35-1.40 gm/cc

- Solid content – 45-50 %

- Dilution Ratio – DECAFLUX G W P 1020:WATER – 1:0.75 to 1:0.80

- Application Viscosity (By B4 Cup) – 13-16 seconds

APPLICATION TECHNIQUE:

- DECAFLUX G W P 1020 is used for Grey Cast Iron, S. G. Iron & Non Ferrous Alloys castings especially Automobile castings. It can be applied on Cores & Moulds of all types of Resin Bonded Cores.

- It is suitable for Dipping, Spraying, Brushing & Flooding or over-pouring type applications.

- After coating applications, the cores are dried in an oven at temperature between 150-180oC for one hour which ensures uniform, homogenous & dense coating film.

STANDARD PACKING:

DECAFLUX G W P 1020 is available in 40 Kg Poly Bag.

SAFETY PRECAUTIONS:

- Remix the carboys contents thoroughly before transferring it to the dilution tank.

- Monitor the viscosity at periodic intervals especially after every two hours.

- Use slow speed mixer to avoid air entrapment during continuous mixing.

- To avoid formation of bacteria, clean the dip tank weekly.

DECACOTE G A 9050 (Graphite Spirit/Alcohol Base):

DECACOTE G A 9050 is inready to use form dark grey coloured Alcohol base coating containing High Quality Refractory Material and Natural Graphite. It imparts low reactivity to the metal oxides & delivers excellent casting surface finish especially at High Pouring Temperatures.

It is suitable for brushing, dipping applications of Resin Bonded Complex core in the production of the castings like Cylinder Blocks, Cylinder Heads & the hydraulic components. It is recommended for Grey Cast Iron, S. G. Iron & Non Ferrous Alloys.

PHYSICAL PROPERTIES:

- Colour – black

- Baume – 10

- Application Viscosity (By B4 Cup) – 13-16 seconds

- Solid content – 32-40%

APPLICATION TECHNIQUE:

- DECACOTE G A 9050 is used for Grey Cast Iron, S. G. Iron & Non Ferrous Alloys castings especially Automobile castings. It can be applied on Cores & Moulds of all types of Resin Bonded Cores.

- It is suitable for Dipping, Spraying, Brushing & Flooding or over-pouring type applications.

- After coating applications, the cores are dried by ignition for few minutes which ensures uniform, homogenous & dense coating film.

STANDARD PACKING:

DECACOTE G A 9050 is available in 20 Kg Poly bucket.

SAFETY PRECAUTIONS:

- Remix the carboys contents thoroughly before transferring it to the dip tank.

- Monitor the viscosity at periodic intervals especially after every two hours.

- Use slow speed mixer to avoid air entrapment during continuous application.

- To avoid formation of bacteria, clean the dip tank weekly.

DECAPASTE G A 8030 (Graphite Spirit/Alcohol Base):

DECAPASTE G A 8030 is a Graphite water base refractory coating for sand moulds and cores. The coating can be used in the manufacture of ferrous casting. When the mould or core is coated with DECAPASTE G A 8030, it enhances surface refractoriness thereby improving the surface finish of the casting. DECAPASTE G A 8030 is formulated for dip and brushing application.

HOW TO USE:

DECAPASTE G A 8030 is paste and must be diluted with suitable quantity of water and mixed thoroughly for brushing and dipping applications. The mould and core has to be coated with this paint and torch dried or oven dried.

SPECIFICATION:

- Colour – Blackish Paste

Properties of Coating after Mixing with Spirit/Alcohol.

- Specific Gravity – 1.23-1.30 gm/cc

- Dilution Ratio – DECAPASTE G A 8030 – 1:1.1 to 1:1.15

- Application Viscosity (By B4 Cup) – 15-18 seconds

STANDARD PACKING:

DECAPASTE G A 8030 is available in 50 Kg Poly Bag.

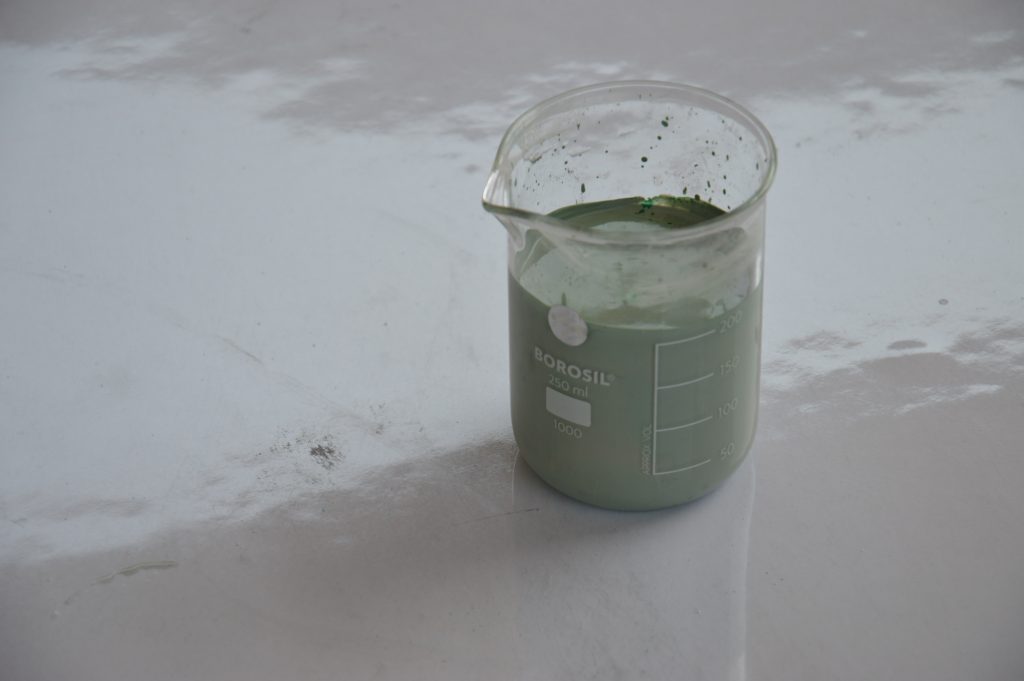

DECACOTE Z A 7040 (Zircon Spirit/Alcohol Base):

DECACOTE Z A 7040 is Spirit based Zircon coating for spraying and brushing applications. A ready to use dressing having excellent suspension and coverage properties,suitable for casting high temperature steel and cast iron.

APPLICATION:

- Product is used for all green sand ,CO2 set and resin bonded sand mould and cores.

- Suitable for spraying ,Brushing ,types of applications.

- Product is specially formulated to ensure high refractory ,non-wet table and non –reactive coating layer with optimum application properties to ensure an excellent casting finish.

SPECIFICATIONS:

- Colour – Faint Green.

- Sp.Gravity – 1.60 +/ 0.03 gm/cc.

STORAGE AND HANDLING:

The product should be stored at a room temperature under the roof and away from direct sunlight and moisture.Use of safety gears and gadgets is a must while handling the above product.

PACKING DETAILS:

DECACOTE Z A 7040 is supplied in 20 kg Poly bucket.

PRECAUTION:

The product should be stored in a cool and dry place.

DECACOTE Z W 6050 (Zircon Water Base):

DECACOTE Z W 6050 is in liquid form off-white coloured Water Based Zircon coating suitable mainly for Brushing application. Due to the presence of High Quality Zircon, It offers excellent thixotropic properties resulting in superior suspension &excellent performance at High Temperatures. It is suitable for use on most sand binder backgrounds & for almost all metal cast, including critical castings in cast iron & steel.

PHYSICAL PROPERTIES:

- Colour – Off-white liquid

- Specific Gravity – 2.0-2.3 gm/cc

- Dilution Ratio – 1: 0.25-0.30 (PRODUCT:WATER)

APPLICATION TECHNIQUE:

- DECACOTE Z W is used for all grades of Cast Iron & Steel & for Aluminium. Also can be applied on Cores & Moulds of Cold Box, Hot box & Shell Resin.

- It is mainly suitable for brushing applications& optionally for dipping/ spraying by slight dilution.

- To achieve homogenous & dense coating film, drying of the coating has to be conducted in an oven at temperature 160oC +/-10oC for one hour.

SHELF LIFE & STORAGE:

DECACOTE Z W has a shelf life of 6 months from the date of manufacture. The product should be stored at room temperature under roof & away from direct Sunlight & moisture.

STANDARD PACKING:

DECACOTE Z W is available in 40 Kg Poly bags.

SAFETY PRECAUTIONS:

- To prevent drying of the coating, replace the lid of the carboy immediately.

- Avoid skin contact& protect eyes from spillage. In case of skin contact, wash with water immediately.

- Do not dilute the content of coating as too much water will reduce suspension & increase penetration into core & mould.

DECACOTE M A 5060 (Magnesite Spirit/Alcohol Base):

DECACOTE M A 5060 is Spirit based Magnesite coating for spraying and brushing applications. A ready to use magnesite coating specially used for manganese casting.

APPLICATION:

- Suitable for spraying ,Brushing ,types of applications.

SPECIFICATIONS:

- Colour – Brownish.

STANDARD PACKING:

DECACOTE M A 5060 is available in 25 Kg Poly bucket.